Projection Welding Machinery

Combination Spot & Projection Welders

Designed to produce high welding forces without deflection, T. J. Snow’s heavy duty press- type resistance welders are available in a variety of set-ups including Spot Welders with arms, Projection Welders with platens, and Combination Spot and Projection with both arms and platens.

Standard AC transformer sizes range from 50-500 KVA, with larger capacities and custom options available. MFDC and Three Phase Frequency Converter power supplies are also available.

Standard Specs of Spot & Projection Welders

- KVA: 50-500 kVA

- Throat Depth: 18″ to 48″ | Vertical Gap Adjustable up to 18″

- Voltage: 220V, 440V, 575V | Single Phase or Three Phase

- Secondary Voltage: 3.6-10 to 7.8-12.9

- Xfmr Tap Switch: 6 or 8 Taps

- Air Cylinder Standard: Dual Action

- Air Cylinder Options: Dual Action, Adjustable Stroke, Dual Action with Retract

- Air Cylinder Stroke: 4″ Standard, 3″ Retract Optional

- Air Cylinder Bore: 4″ to 10″ Available (1,000 to 6,280 lbs. at 80 PSI)

- Platen Size: Standard RWMA Size 1 & 2

- Machine Initiation: Dual Palm Buttons Standard

Larger Capacities Available: RWMA Size 3 and custom frames are available to accommodate resistance welding applications requiring larger KVAs and higher weld forces. Please contact T. J. Snow’s Application Department for additional information.

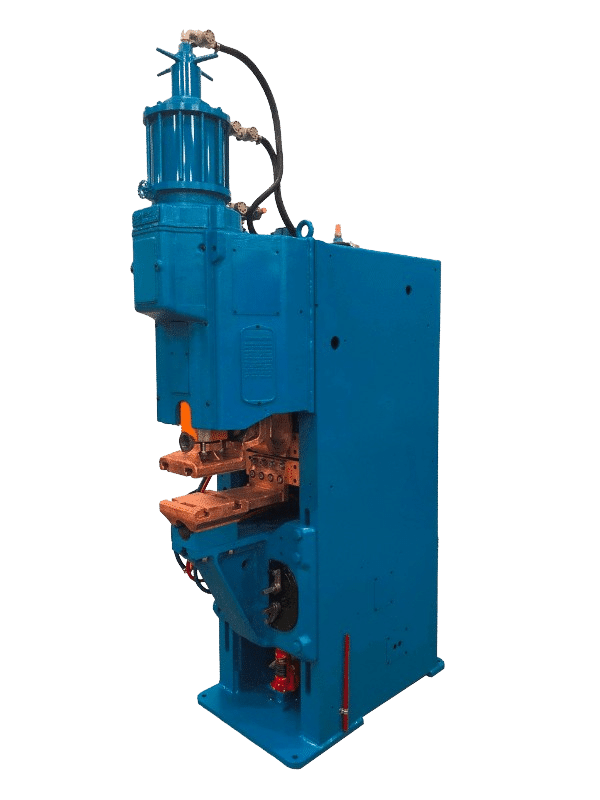

Refurbished projection welder with t-slotted plattens

Add-Ons for Spot & Projection Welders

- Pressure Switch

- Programmable Air

- Removable Arms & Tip Holder for Spot Welding

- Bucking Air

- Foot Switch (Key Selectable)

- Light Curtain

- Adjustable Stroke Air Cylinder

- Water Chiller

- Water Flow Indicators

- Water Flow Switch

- Water Saving Circuit

- Nut Feeders

- Turret Head(s)

Applications for Projection Welding

Projection welding can be broken down into three main categories, all of which involve just one stroke of the machine.

- Welding of multiple individual projections

- Welding of ring projections

- Welding of crossed wire joints

The most common form of projection welding involves attaching fasteners, such as nuts and studs, with typically three or four projections to focus the heat. Other common applications involve welding multiple projections embossed in sheet metal.

Ring projection welding creates an air or water tight seal.

Welding of crossed wire fabrications presents the perfect point-to-point joints

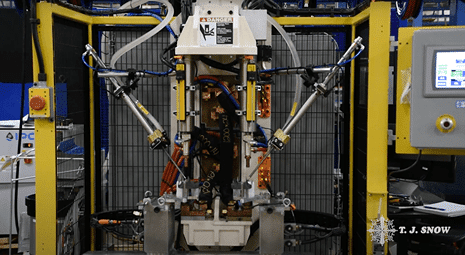

Custom resistance projection welder with automated nut feeders

What is the Difference Between Spot Welding & Projection Welding?

Spot welding is accomplished with pointed electrodes that concentrate the heat. These electrodes mushroom with use and must be redressed or replaced. The beauty of projection welding is that the electrodes are flat and serve only to conduct the welding amps to and through the projections, which results in the equivalent of a new set of electrodes for each weld.

Ready to Discuss Your Resistance Welding Solution?