Spot Welding Robots

Since 1981, T. J. Snow has a proven history of designing and integrating robotic arc and robotic spot welding cells. T. J. Snow is a MOTOMAN Solution Provider.

Spot Welding Automation

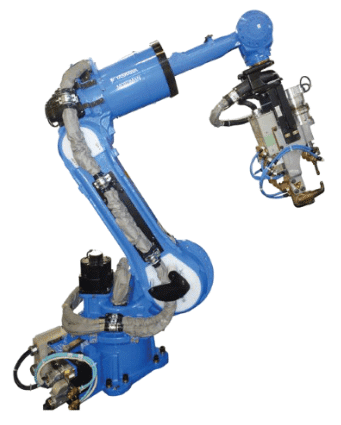

MOTOMAN innovations in the robotic spot welding market include ES-series “Expert Spot” robots with an integrated spot harness. With spot utilities (power, water, air, motor and signal lines) integrated into the profile of the robot arm, automative OEMs and Tier 1 suppliers realize increased flexibility and higher uptime. MOTOMAN’s patented multiple robot control technology allows close interaction of several arms working on a car body without fear of collision.

MOTOMAN latest innovation is the 7-axis VS50 spot welding robot. Designed to take full advantage of proven Direct Current (DC) weld times and servo-controlled actuators. MOTOMAN is introducing a series of light weight “mini-guns.” These powerful, compact spot welding guns weigh less than 50kg, but deliver high performance with 600 kgf clamping pressure and 15,000 amps of welding current. The low profile and “elbow” on the VS50 robot allow it to be positioned close to the vehicle. It can reach underneath or inside confined spaces. The 6-axis MS80 robot complements the 7-axis VS50 arm and has a slim profile and longer reach for windshields and pillars. These smaller, faster spot welding robots are designed to be used with full-size ES165/200 robots with larger guns to maximize robot density in a welding station. This “high-density” approach reduces takt time and shortens the production line with fewer re-spot stations.

Spot Welding Robot Models:

MS80

VS50

ES165N

ES200N

HP350

If you are interested in more information feel free to give us a call or email so that we can talk over your specific situation.

T. J. Snow is a MOTOMAN Solution Provider

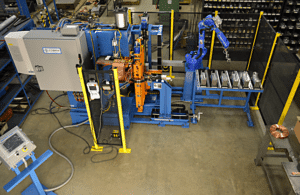

Fully Automated Seam Resistance Welding Machine for Transportation Client