Weld Testers

Weld checkers, testers and weld monitors measure one or more of the electrical and/or mechanical parameters that dynamically change during the resistance welding process. These parameters include weld current, voltage drop across the electrodes, work piece expansion and deformation, electrode force, electrode displacement (movement) and more.

Resistance welding process monitors (weld checkers) measure and monitor the different variables that are simultaneously occurring during the resistance welding process. These tools help identify areas of improvement and overall process development.

Dengensha WS-100

The WS-100 monitors the secondary current and cycle time of resistance welders during the welding cycle. The results are shown on an LCD display screen which offers the choice of current measurement, waveform, history and system screens. The unit also includes a USB interface to a PC to allow easy conversion of the weld history to a .CSV file.

Dengensha WS-80

The WS-80 monitors the secondary current and cycle time of resistance welders during the welding cycle. The results are shown on a fluorescent display and can be sent to the included printer in both numeric and waveform format. The internal memory stores up to 800 data items measured consecutively. Any measurements that exceed the specified range are reported by visual alarm, buzzer sound and a relay output.

WM-200A IIoT-Ready Networked Resistance Weld Monitor

- Industry 4.0 Networked product to visualize manufacturing around the globe

- High speed, full waveform data acquisition and visualization for deep view into welding process for R&D and manufacturing settings

- Standard data format outputs for easy handling in advanced data analysis software and AI/ML algorithms

- Monitor multiple all key weld parameters in regions of interest simultaneously for better control of production

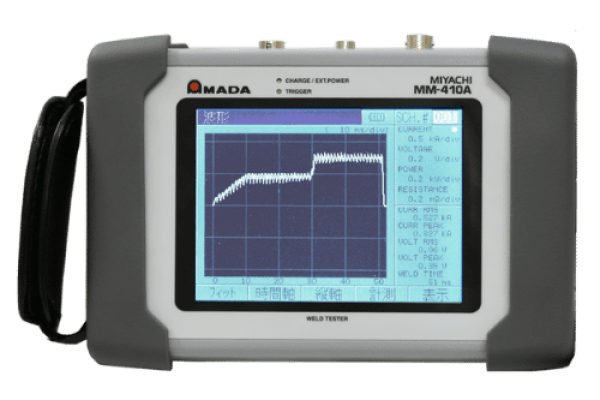

Miyachi MM-410A

- AC, DC inverter, AC inverter, transistor and capacitive discharge

- Improved accuracy through ISO 17657 compliant toroidal coil

- Easy setup via 5.7″ color touch panel

- Seam weld mode – Monitor AC current and voltage or DC voltage for up to 5 minutes

- ISO 17657 – compliant measurement for current – Requires ISO-compliant toroidal coil

- Data storage via on-board flash drive

- Ethernet (TCP/IP) and USB connection

- Multi-language support: English, Spanish, Japanese, Chinese, Korean, German, and French

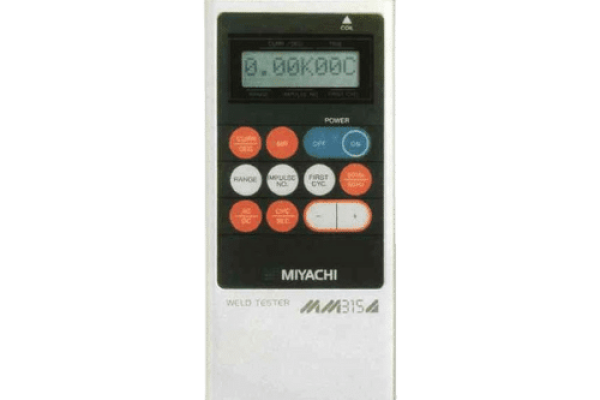

Miyachi MM-315A

- Measures weld current, weld cycles, milliseconds and conduction degrees

- For AC and Inverter power supplies

- Automatic power-off system

- Up to 9 impulse memory capacit

- Easy view LCD screen

- Oil and dust proof case

- Toroidal coil, battery charger and carrying case included

- Memory function for easy recall of impulses

Miyachi MM-123A

- Measures Single Phase AC, DC Inverter, AC Inverter, Capacitor Discharge, Transistor

- NEWLY ADDED – Voltage Monitoring

- Allows you to monitor voltage & current at the same time

- Improved measuring precision

- Enables to measure the RMS based on ISO 17657 without any exceptions

- Upper/Lower limit judgment

- Detection of errors that can occur

- Long time measuring

- Available for measuring in 3000ms

Miyachi MM-400A

MM-400A enables operators to monitor and manage key welding variables that result in changes in weld heat such as current, voltage, time, force and displacement. The compact unit supports a wide range of resistance welding technologies including AC, DC inverter, AC inverter, transistor and capacitive discharge. It features a simple and intuitive user interface and color touch panel display.

WeldComputer WeldView

The WeldView Monitor for resistance welders provides a comprehensive and cost-effective means of ensuring the integrity of every welded product. It typically performs more than a thousand separate checks on every production weld to verify the performance and repeatability of the process. During each weld, voltage, current, conductance, and power profiles are automatically monitored. Force and displacement measurement profiles are also available options to provide the most comprehensive weld quality monitoring.

ENTRON WA2 Weld Analyzer

Analyze, identify, and improve resistance welding process quality with ENTRON’s portable, durable WA2 Weld Analyzer. This sophisticated test equipment is suitable for today’s superior resistance weld control systems.

TECNA TE1700 Weld Checker

The TECNA TE1700 Weld Checker is specifically designed to help make your process the most effective and efficient it can possibly be. The utilization of different probes allows you to measure weld current, force, voltage, energy, resistance and thermal current all on one 6″ color LCD touchscreen in various formats, including the waveforms of the selected signals. The TE1700 is suitable for measuring AC, DC/MFDC, and CDW currents. And with a name like TECNA behind it, you know you’re going to get the quality you deserve from a name you already trust.

Weld Checker Comparison Chart

Brand | Style | Model | Measurement Types | Current Ranges | Measured Schedules | Cycles | Voltage | Conduction Degrees | Select Impulse # | Select Weld Segment (Cycles) | Upper & Lower Limits | Price | Data Output/Memory | Printer | Pre-set Counter | Notes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Amada Weld Tech | Stand-alone | AC, AC inverter, DC inverter, capacitor discharge | 2-200 kA | 128 | AC: 0.5-2000 DC: 1-5000 ms | YES | YES | YES | Multiple Segments | YES + Envelope | $$$$$ | Ethernet with Server | NO | YES | Industry 4.0 Networked monitor with Server for data logging | |

Amada Weld Tech (formerly Miyachi) | Hand held portable | AC, DC inverter, AC inverter, transistor, capacitor discharge | 0.100-2.000 kA 0.30-6.00 kA 1.00-20.00 kA 3.0-60.0 kA 10.0-200.0 kA | 127 | AC: 0.5-250.0 CYC (50 Hz), 0.5-300.0 CYC (60Hz) or 1-5000 ms | YES | YES | YES | First & Last | YES | $$$$ | USB / Ethernet (Protocol: TCP/IP) | No | No | 5.7" color touch panel. Measure and graph force (optional Current/Force sensor required) | |

Amada Weld Tech (formerly Miyachi) | Hand held portable | AC & inverter power supplies | 1-9.99 & 5-49.9 kA RMS | 1 | AC: 1-99 DC: 1-40 cycles | NO | YES | YES | First Cycle | NO | $ | None | No | No | MB-500-15 Toroidal Coil included | |

Amada Weld Tech (formerly Miyachi) | Stand-alone | AC, DC inverter, AC inverter, transistor, capacitor discharge | 0.100~2.000kA / 1.00~20.00kA / 10.0~200.0kA | 31 | AC 0.5~150 cycles AC inverter: 0.5~max. 1500 cycle | YES | YES | YES | First & Last | YES | $$ | Ethernet (Protocol: TCP/IP) | Optional | Suggested Toroidal coil: MB-400M or MB-800M | ||

Dengensha | Large portable | AC, DC inverter, capacitor discharge, three-phase frequency converter | 0.5-100 kA | 16 externally selected | 1-99 cycles | YES | YES | YES | First & Last | YES | $$ | Stores up to 800 welds RS-232/485 & I/O | Built-in thermal printer | N/A | Plug-in unit, toroidal coil included model 1B8L | |

Amada Weld Tech (formerly Miyachi) | Large portable | Single-phase AC, DC inverter, AC inverter, transistor, capacitor discharge | 0.10-200 kA | 127 | 0.5-2000 cycles or 1-5000 ms | YES | YES | YES | First & Last | YES | $$$ | RS-232C / RS-485 / Ethernet (Protocol: TCP/IP) | Built-in printer | N/A | ||

WeldComputer | Large portable | AC & DC single phase, three-phase, capacitor discharge, or inverter type | .001A-999.9 kA | 10,000 | 0.5-32000 cycles or 10 us- 10 min | YES | YES | YES | First & Last | YES | $$$ | Local storage for 1,000,000 welds (typical). Standard data over network or removable media & I/O | Export to PC for printing | N/A | Optional pressure, force & displacement sensors available. Multichannel units also available. | |

Dengensha | Hand held portable | AC, DC inverter, capacitor discharge, three-phase frequency converter | AC: 0.6A-50 kA DC: 1A-50 kA | 1 | AC: cycles DC: ms | NO | YES | YES | First & Last | NO | $ | RMS current & time: 10,000 points RMS current of each cycle: 50 pts Waveform: 3 pts USB Type B to PC and software | Export to PC for printing | N/A | 1B4S3UL 400mm Toroidal coil (included) IB8s3UL 800mm Toroidal Coil (sold separately) Optional pressure sensor up to 10kN | |

Entron | Hand held portable | AC, MFDC | 1A-60kA | 1 | AC: cycles DC: ms | NO | YES | YES | First & Last | YES | $ | Limited on-board storage dependent on weld data size. USB mini B to PC and software | Export to PC for printing | N/A | Optional attenuator for up to 300kA. Integrator output to connect an oscilloscope or other recording instrument if required. | |

TECNA | Large portable | AC, DC / MFDC, CD | 4-190 kA | 16 | AC: 1-99 cycles DC: 1-200 ms | YES | YES | YES | Adjustable | YES | $$$ | Internal storage, Wi-Fi, ethernet, USB | Export to PC for printing | No | Unit also measures force, has built in welding tables & graphical view of force & current |