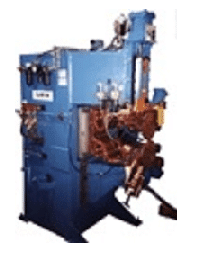

Remanufactured & Reconditioned

Spot Welders

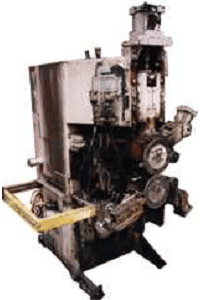

In addition to new resistance spot welding machines and solutions, T. J. Snow offers services for existing spot, projection and seam welders including remanufacture, refurbish, retool and rebuild.

Refurbished & Remanufactured Welders

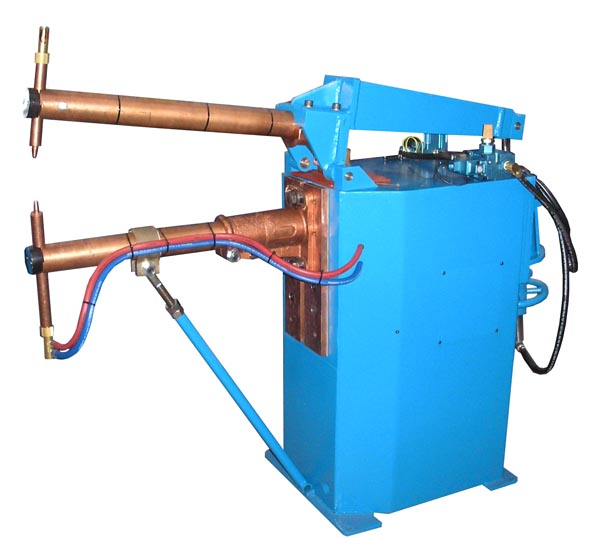

Spot Welders, Projection Welders, Seam Welders

A used resistance welding machine, either the customers existing machine or one selected from T. J. Snow’s extensive inventory of used resistance welders, is stripped down to the last nut and bolt. The machine frame is then professionally sandblasted and spray painted with high quality industrial enamel.

Components are all cleaned and checked for wear. Any part not meeting new machine tolerances is either remachined or replaced.

The welding transformer, is subjected to the same tests for moisture and short circuits as a new unit must pass. If any problems are detected, the transformer is completely rewound with new insulation as required.

- Mechanical

- Roller bearings/ cam followers and other moving parts are often replaced

- Electrical

- Inspection of proper fit-up of the welder’s copper secondary connections, from the transformer out to the electrodes

- New wiring

- New solid state weld control with current software

- Initiation (foot switch, dual palm button)

- Air

- Install new Filter-Regulator-Lubricator (FRL)

- Air cylinder is rebuilt or replaced

- Cylinder walls are machined if necessary

- Cylinder packings, bushings and glands are replaced

- Water

- Install new water circuit

- Including visual flow indicators and visual petcocks

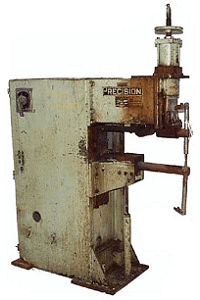

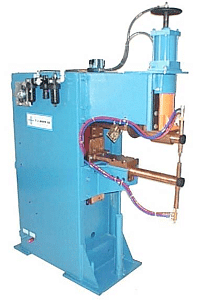

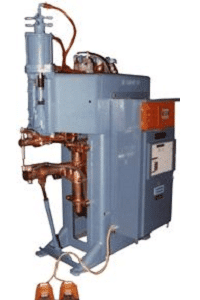

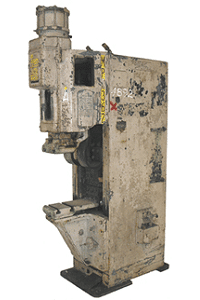

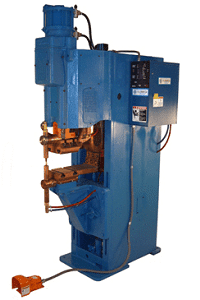

Before and After the Remanufacturing Process