Seam Weld Head Repair

T. J. Snow Company seam head experts can repair and rebuild your used or worn seam weld head at a fraction of the cost of a new seam head. Similar to a car transmission, periodic and preventative maintenance will extend the seam weld head’s life cycle.

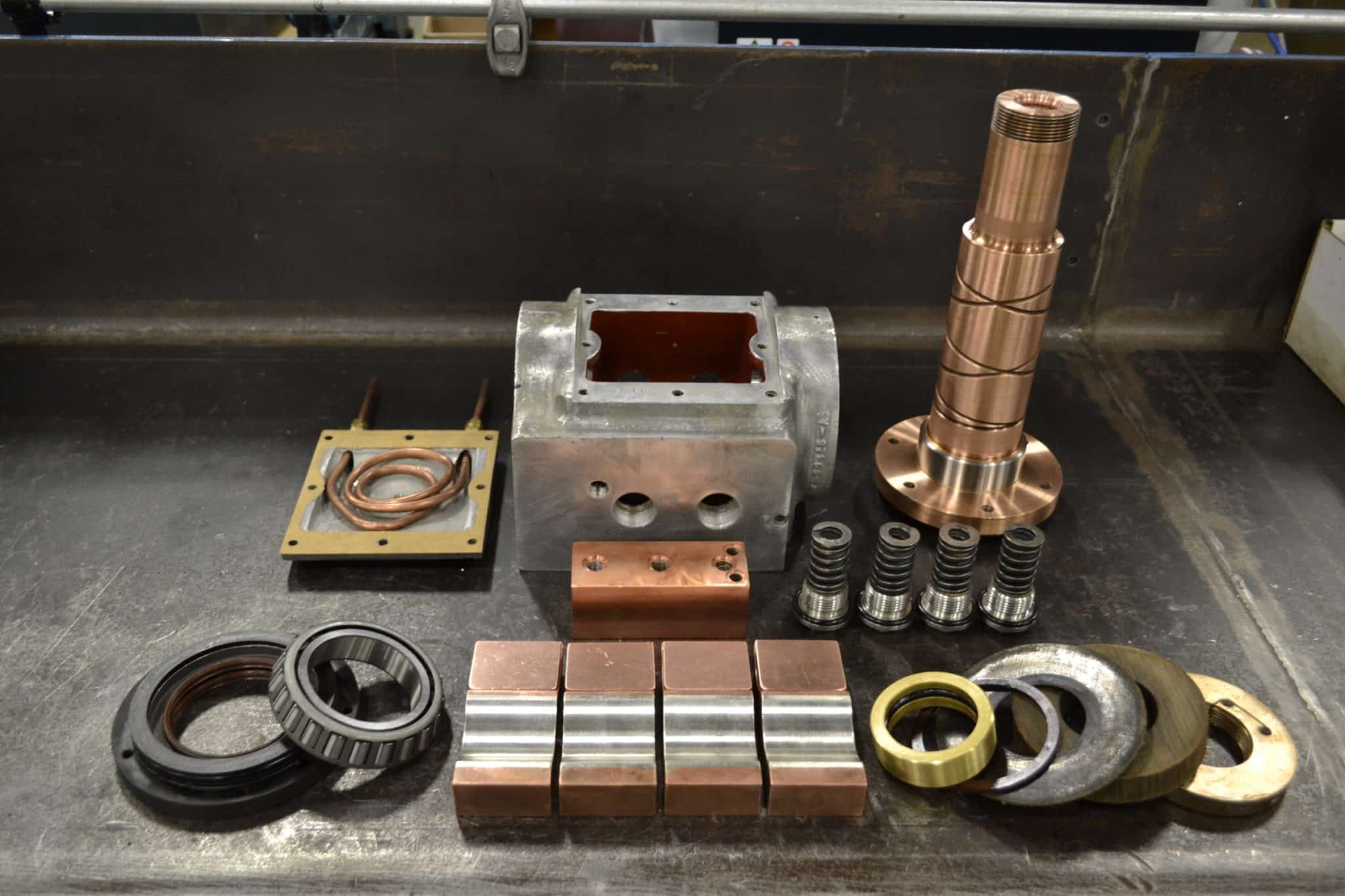

Experienced mechanics strip the worn seam weld head.

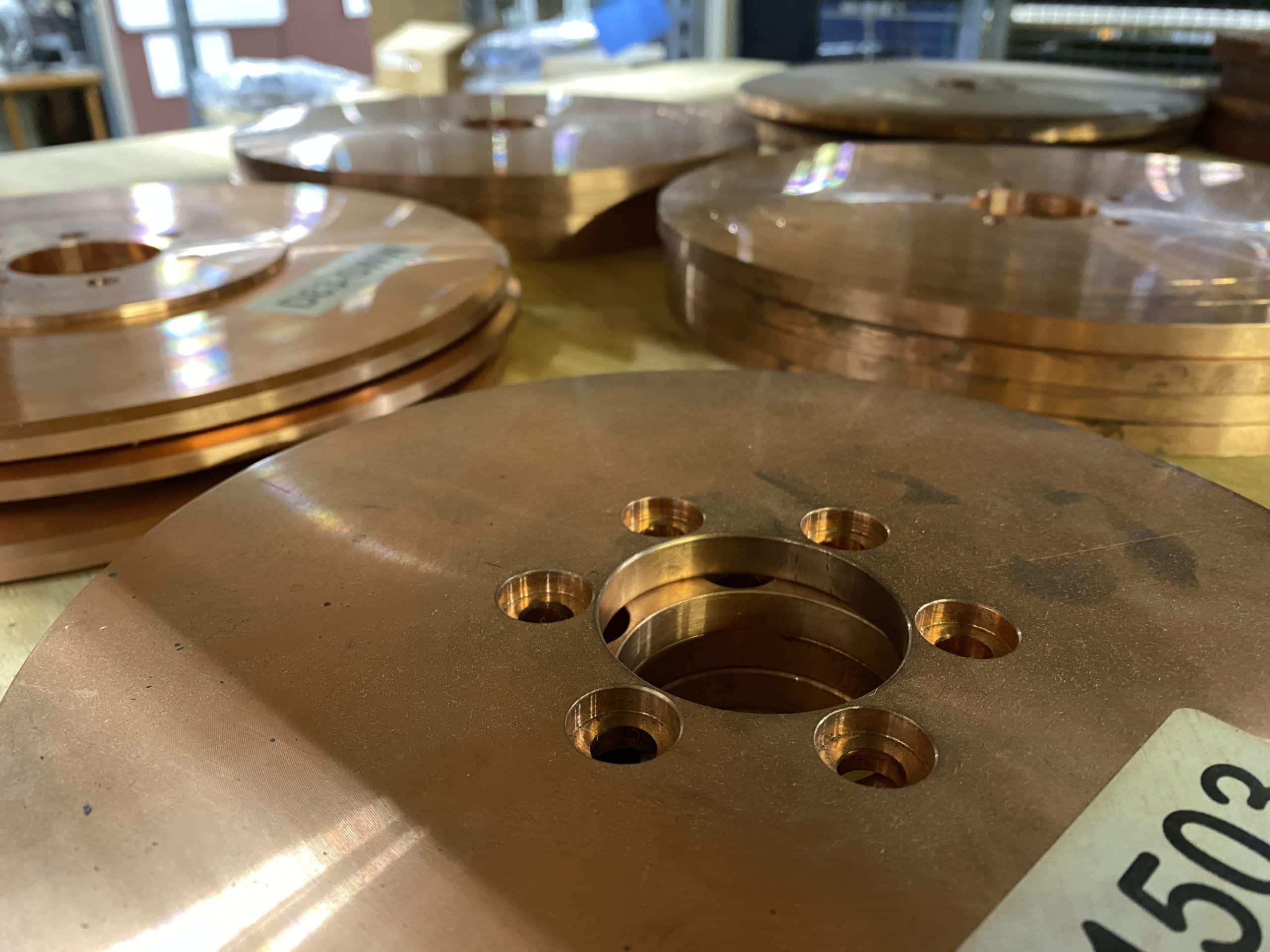

All components are cleaned and checked for wear.

Particular attention is paid to proper fit-up of the secondary connections.

Mating surfaces are checked for flatness.

They are remachined as necessary to remove any pitting caused by wear or loose connections that existed prior to the tear-down.

Contact springs and shunts are inspected.

Contact springs are checked for correct pressure and are replaced as necessary. Contact shunts are inspected for wear and replaced as needed.

All contact pads are re-silvered.

All bearings, seals and insulators are replaced.

For air cylinder and seam head repairs, please complete the form below and include with your items to ensure quick turn around.

Take Advantage of Our Comprehensive Repair or Rebuild Services

Contact Aaron Oster at AaronOster@tjsnow.com or (423) 308-3216. Fill out our Service Repair Sheet and include it when you send in your seam weld head.

Once we receive the head, we will open it up and evaluate its wear and internal components for possible damage. Once the evaluation is complete, our Service Department will contact you with a quote to bring your seam weld head to a functional condition. All initial evaluations are subject to fees.

All repairs and rebuilds of seam weld heads are performed in-house at our Chattanooga, Tennessee facility. We have many years of experience rebuilding or repairing all types of resistance seam welding heads.