What is Resistance Welding?

Resistance welding is a high-speed method of joining metals by applying pressure and electrical heat under accurate controls, making a weld in a fraction of a second.

How Does Resistance Welding Work?

The Resistance Welding Process

In a resistance weld, a large amount of welding current is passed through a concentrated area – also known as the weld zone – for a specific time while being held under a localized forging pressure. Heat energy is generated when an electrical current passes through an electrical resistance.

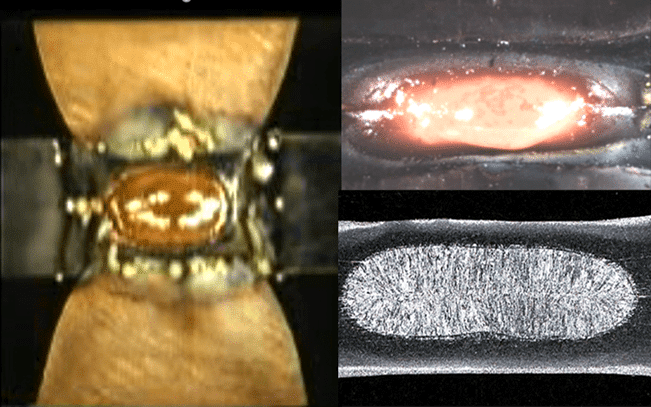

Since resistance is the highest at the faying surfaces (part to part interface), a greater volume of heat is generated at that interface allowing the metal to become molten. A forging pressure is applied at the molten area and the work pieces will alloy together to form a weld nugget.

Closeup of a spot welding nugget being formed.

What is the Formula for the Resistance Welding Process?

The formula for making a good resistance weld includes the proper amount of force, current, time and temperature.

Force / Pressure

The clamp force used to forge the materials together and contain the molten material unitl the Weld Zone solidifies.

Current

By passing through the resistance of the weld zone, electrical current performs the task of creating the required heat.

Time

Time is another important variable in the resistance welding process. Longer weld times are often improperly used to correct a problem with the weld recipe.

Temperature

Resistance welding electrodes should be properly cooled with a closed loop water chiller system.

What Are the Different Types of Resistance Welding?

Spot Welding

Spot welding is the most common form of resistance welding. Opposing electrodes or tips conduct and concentrate welding current and apply forging force to form each weld.

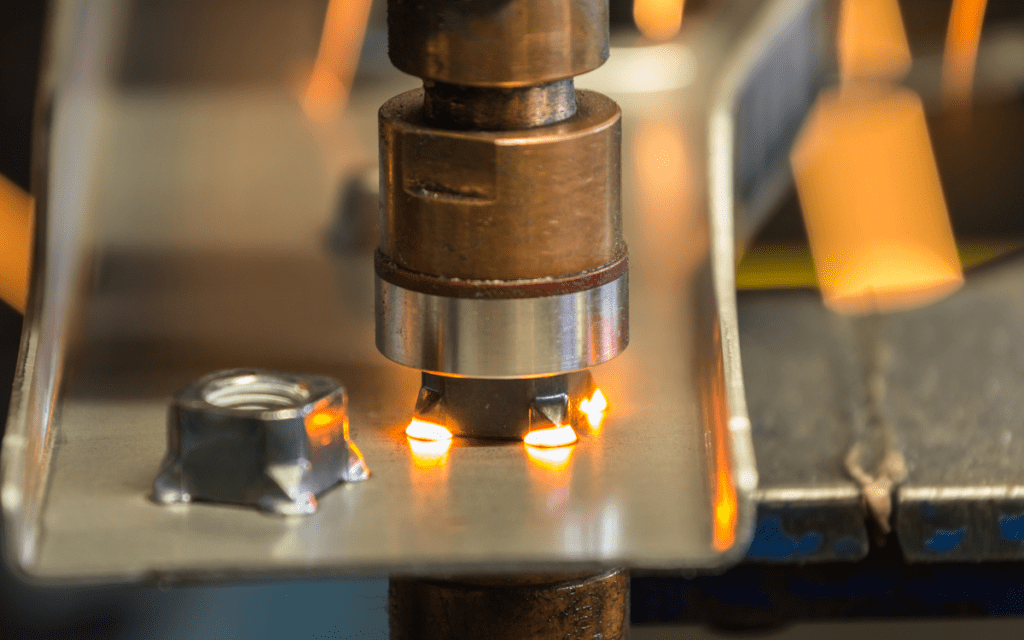

Projection Welding

Projection welding is similar to spot welding except that embossed or solid projections in the part being welded concentrate the heat and form the welds. Multiple projections can be welded with one stroke of the machine.

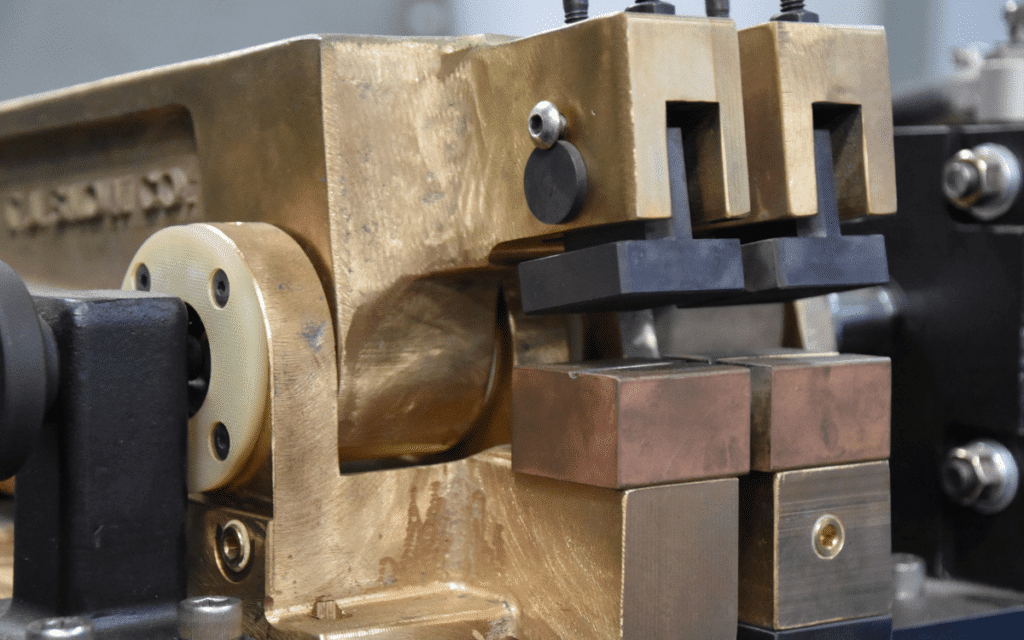

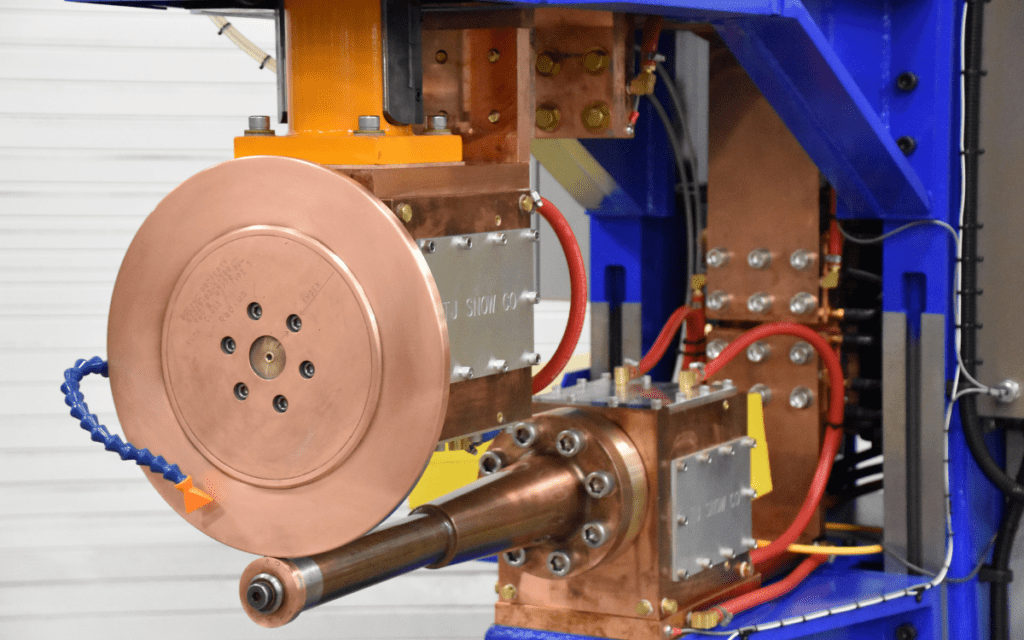

Seam Welding

Seam welding is accomplished with a machine equipped with copper wheels (round electrodes) that rotate and produce a continuous or intermittent weld joint.

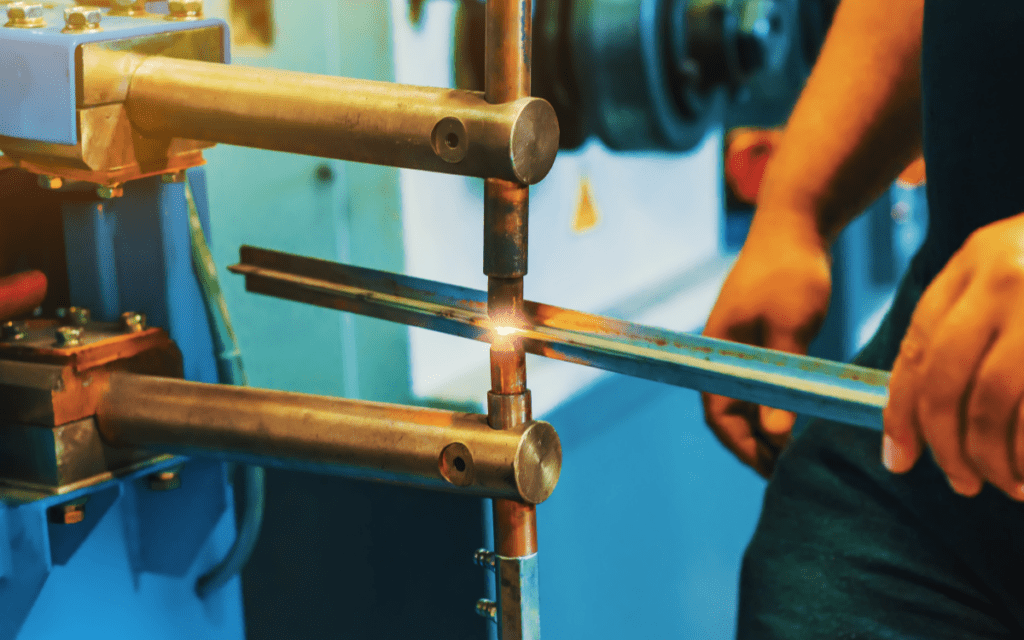

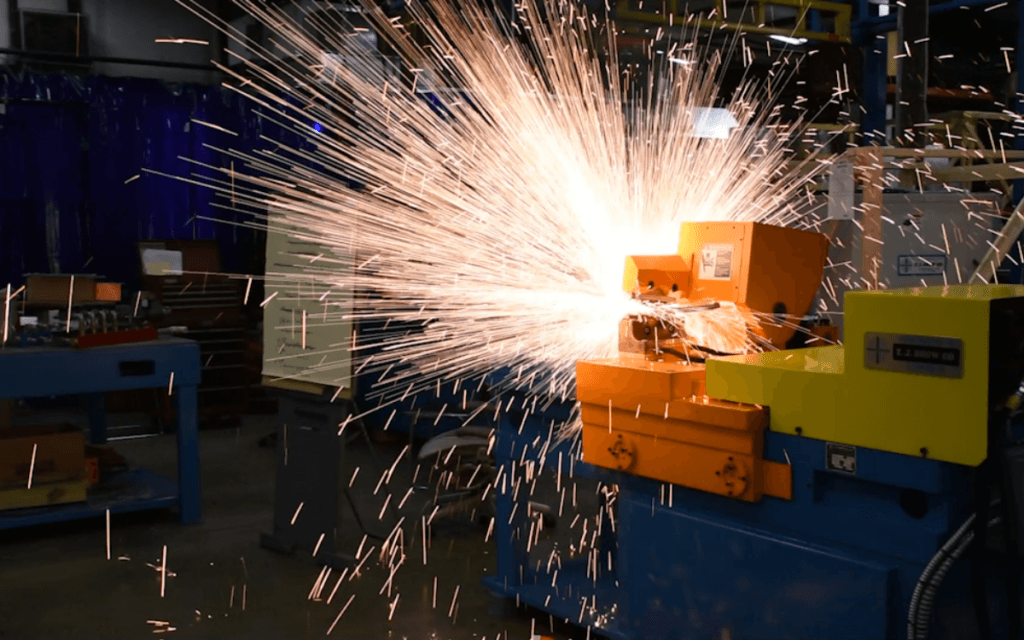

Flash Welding

Flash welding is used to butt weld large diameter parts together.

What Advantages Does Resistance Welding Have Over Other Forms of Welding?

When properly applied, resistance welding has many advantages over other metal joining methods including a low cost and little operator training required.

High Speed

High Strength

Low Cost

Minimal Operator Training

How Can I Learn More About Resistance Welding?

Resistance Welding Training

Once proper parameters are developed, a resistance weld is a fast and efficient way of joining two metals together without the use of gases or filler metals. The welding process can be continued automatically as fast as the material can be fed to the machine.

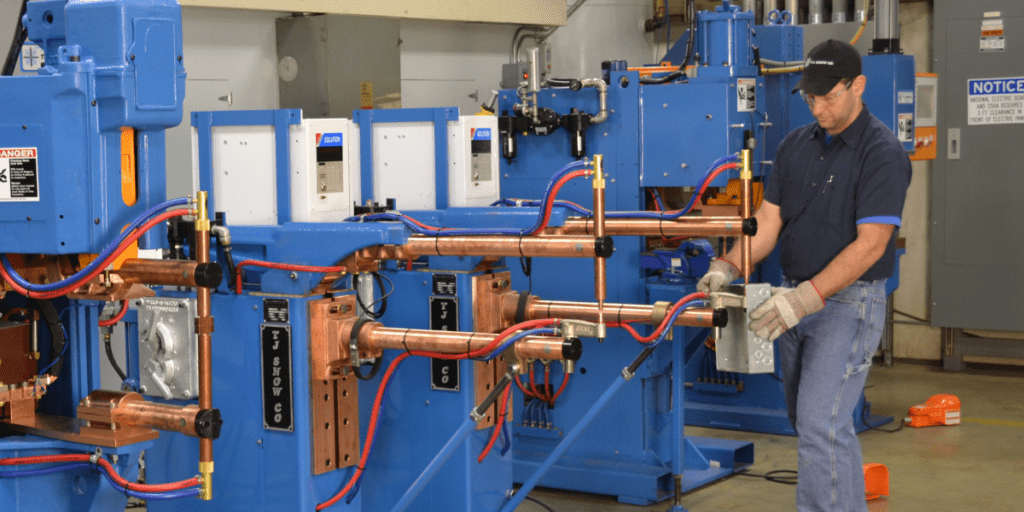

T. J. Snow has a deep understanding of the resistance welding process. We design, manufacturer and deliver solutions that improve quality, durability and productivity. Our engineered solutions deliver improved performance and consistent results.

To gain a better understanding of the resistance welding process, T. J. Snow offers a variety of training options including seminars hosted at your plant and classes offered throughout the United States.