Ready to Discuss Capacitor Discharge Solutions?

T. J. Snow Resistance Welding Machinery, Supplies & Service > Welding Machinery > Capacitor Discharge Resistance Welding

Capacitor Discharge (CD) Resistance Welding

Capacitor Discharge Welding Options for Projection Nut and Stud Welding

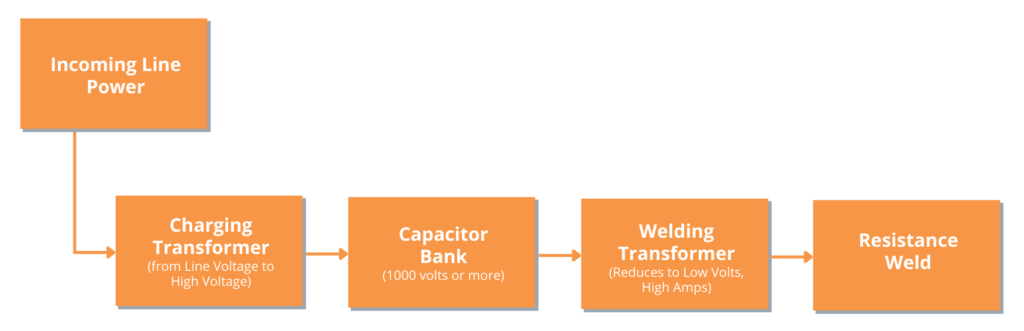

Capacitor Discharge Resistance Welding (or CD Welding) is a fast, special form of Resistance Projection Welding in which the welding energy is provided by the release of energy stored in a large capacitor bank.

Designed for high-precision and mass production, capacitor discharge resistance welding solutions are available from T. J. Snow ranging from 1 – 160 kJoules.

Capacitor Discharge (CD)

Welding System

Available in 12 – 24 kJoule

Standard 18″ – 24″ Throat Depths

Standard RWMA Size 2 Frame

-

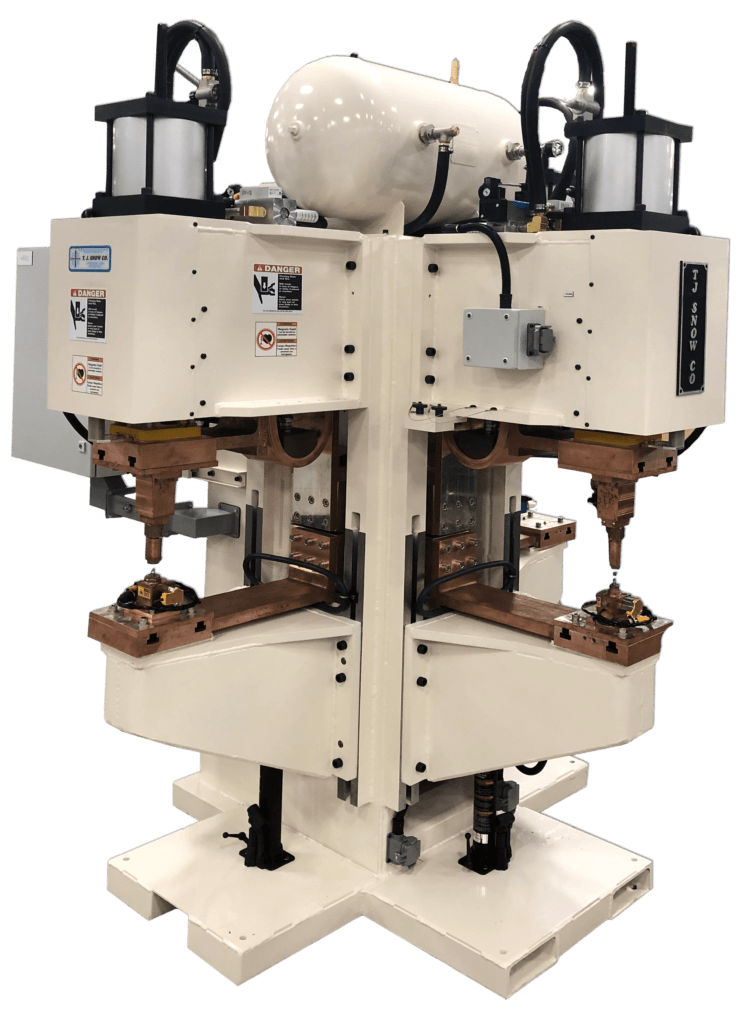

Multi-Pulse Capacitor System

T. J. Snow's Capacitor Discharge Welding System features 4 independent capacitor banks - 2 small and 2 large - permitting the capacitor energy to be released simultaneously or cascaded to allow removal of unwanted coating with a pre-pulse or a final tempering pulse.

-

"Elastomer" Fast Follow Up System

As the welding force builds to the set force, the elastomer puck is compressed and stores energy. As the projection begins to collapse, the elastomer puck releases the stored energy linearly and maintains the necessary welding force.

-

Standard Programmable Force & Force Monitoring

T. J. Snow's Capacitor Discharge Welding System is equipped with programable force provided by a proportional valve and monitored by a force transducer. The force transducer allows the actual force to be monitored throughout the entire weld to assure that proper force is applied at all phases of the weld.

-

Optional Cabinet Locations

The CD cabinet can be located on the left or right of the welder frame or can be remotely located up to 10 meters from the welder frame.

-

Additional Configurations

T. J. Snow's Capacitor Discharge Welding System is available in 2 and 3 head models. Nut and part feeders can also be easily integrated into the system.

Benefits of Using Capacitor Discharge Welding

Shorter Weld Times

The Capacitor Discharge (CD) Resistance Welding process utilizes stored energy rather than conventional processes which use direct demand on incoming power. This allows for very short welding times – typically in 10 milliseconds or less.

Minimal Heat-Affected Zone

The short weld time ensures a minimal migration of heat into the area immediately surrounding the weld nugget, thus limiting – or virtually eliminating – alteration of the grain structure (softening in the HAZ).

Concentrated Welds

The resulting short weld time guarantees that the energy required to perform the weld is confined more closely to the weld area.

Power & Cost Savings

An upgraded power service to your building is often not needed as the high electrical energy required is not taken directly from the power distribution network but from a bank of capacitors, which stores the energy and recharges between welds.

How Does a CD Welder Work?

Play Video about cd welding

The CD Resistance Welding process is ideal for quick and repeatable mass production processes that require tight dimensional tolerances. Capacitor discharge resistance welding is ideal for projection, press-fit and annular ring projections up to 4.5″ in diameter. Low marking welds can be better achieved due to the small heat affected zone and dissimilar metals that can often not be welded using conventional resistance welding can be successfully welded using capacitive discharge resistance welding.

3-Head Capacitor Discharge Resistance Welding System

More Advantages of Capacitor Discharge Welding

• Instantaneous high secondary currents

• Minimal heat affected zone

• High operating efficiency

• Ideal for show surfaces

• Minimal alteration of work piece metallurgy

• Minimal surface deformation

• Minimal spatter

• No power service upgrades necessary (provided 3-phase primary power is available)

• Long electrode life (usually does not require cooling due to low heat impact)

• Extensive process monitoring

• Low equipment maintenance

• An effective solution for welding dissimilar materials

• Excellent results possible for projection welding of press hardened and hot stamped materials (22Mnb5)

• Data collection and monitoring standard in all models

• Systems available in 2 and 3 head models

• Nut and part feeders can easily be integrated

Capacitor Discharge Resistance Welding is ideal for mass produced products in the automotive, appliance, electrical sectors and more.

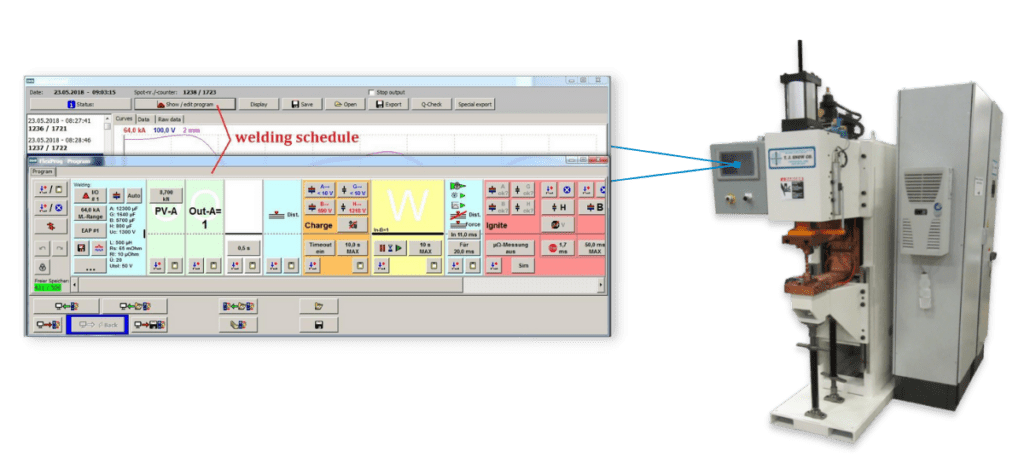

Data Collection & Analysis

The controller features an extensive data collection system capable of storing 100,000 records consisting of graphs, important parameters, and the complete welding program.

Real-Time Data Collection of Key Categories

-

Force

-

Current

-

Displacement

-

Resistance

Glamatronic 60 kJoule CD Welding System

Capacitor Discharge Welding Prototyping Capabilities

- Glamatronic 60 kJoule CD Welding System

- Capable of producing 300,000 secondary amps at 120 kN welding force

- 6 kJoule, 10 kJoule, 45kJoule CD Welding Systems

- Full Metallographic Lab for Analysis of Customer Samples

- 10,000 Tensile Tester

- 2 Staff Welding Engineers for Assistance with DOE and Process Development

Send us your sample parts for evaluation in our lab!