Seam Welders

Resistance Seam Welding Machines

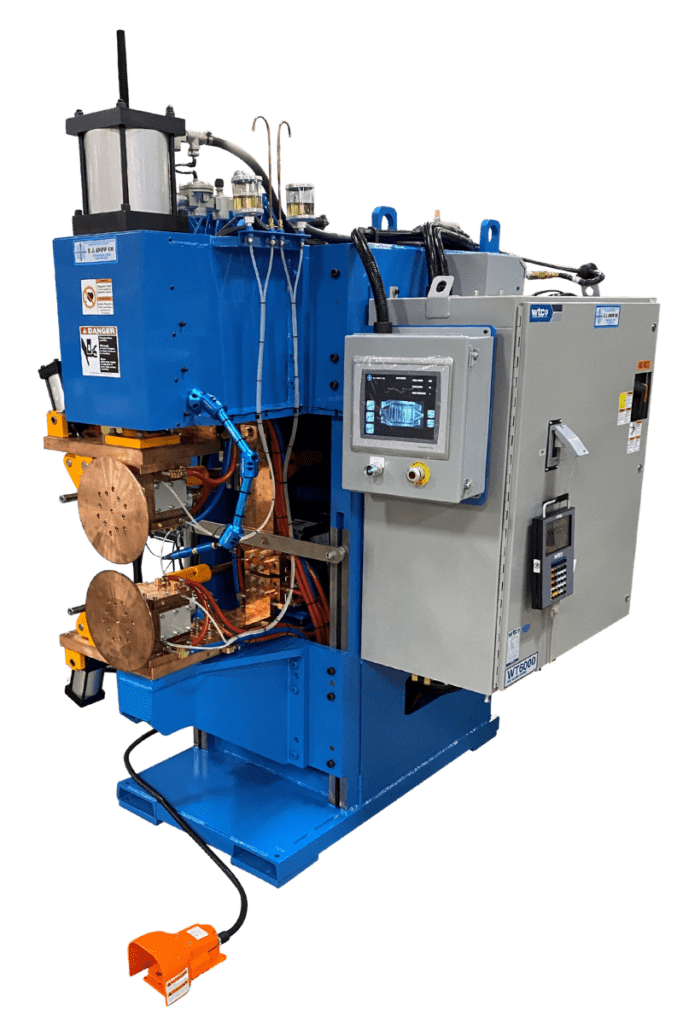

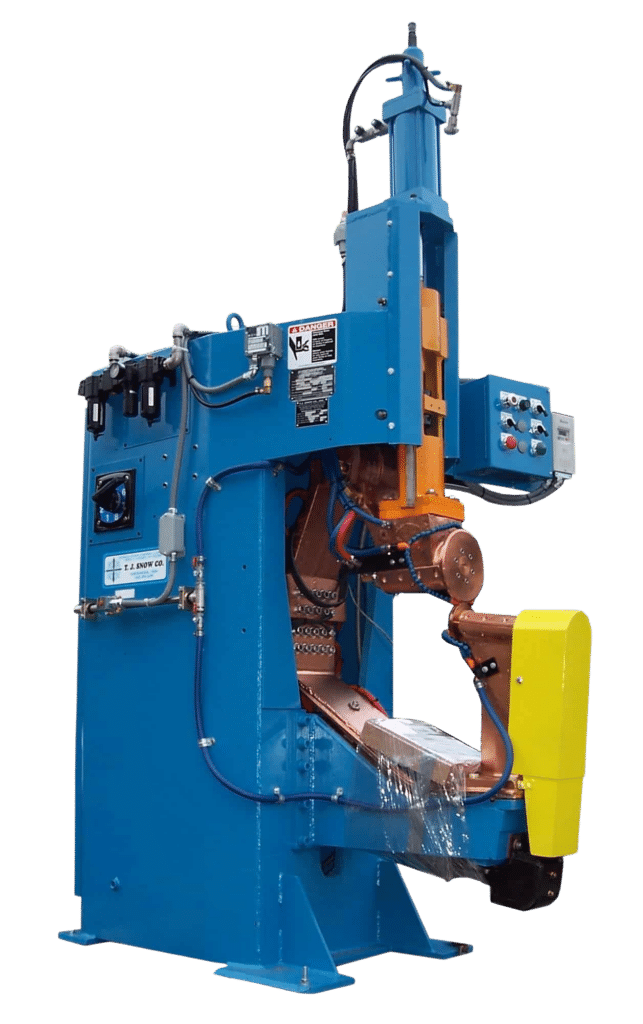

T. J. Snow manufacturers standard and custom resistance seam welding machinery for a variety of applications in the metalworking industry. Our seam welders feature a robust, heavy-duty frame that offer versatility and high-performance.

Resistance Seam Welders

Resistance seam welders are built similar to press-type resistance welders except that the welding force is applied with two rotating copper wheels and the control adjusts the rotating speed and secondary amperage output. The resulting welds are continuous seams, overlapping spot welds, or evenly spaced roll spot welds. The machines are typically configured as circumferential (circular) or longitudinal. Although rare, there are seam welders that are convertible from circumferential to longitudinal.

Continuous sprays of water are directed from water nozzles to the welding wheels and onto the work as it passes through the welder. This is done to minimize warpage from heat as the metal passes between the wheels, overheating or discoloration of the parts and as a means of extending the life of the seam-welding wheels.

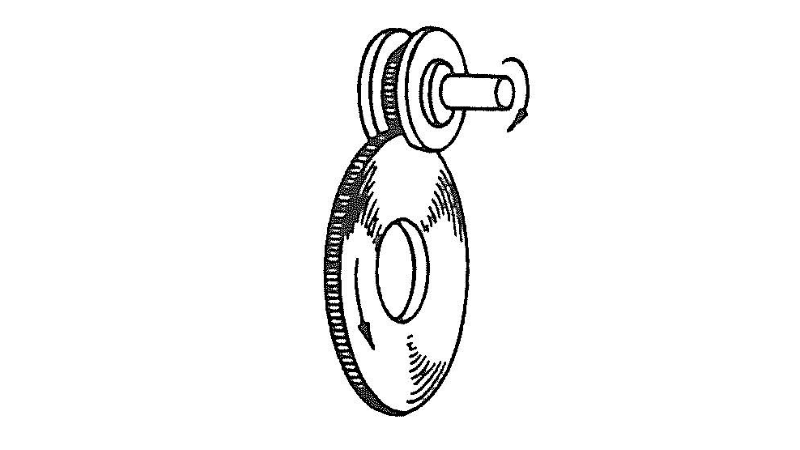

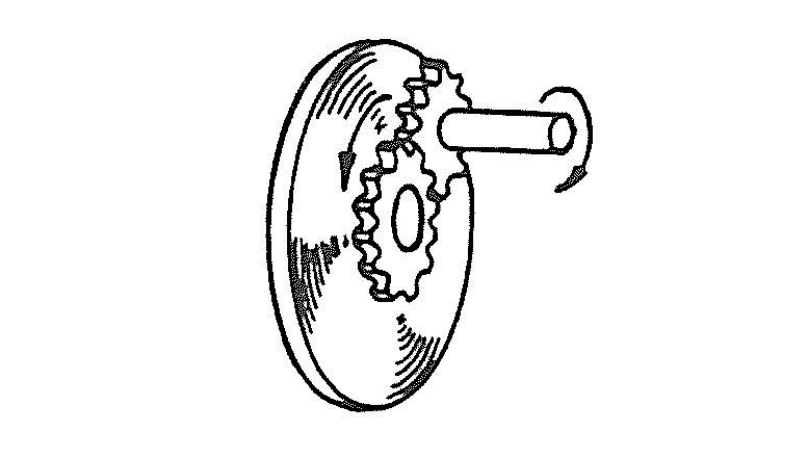

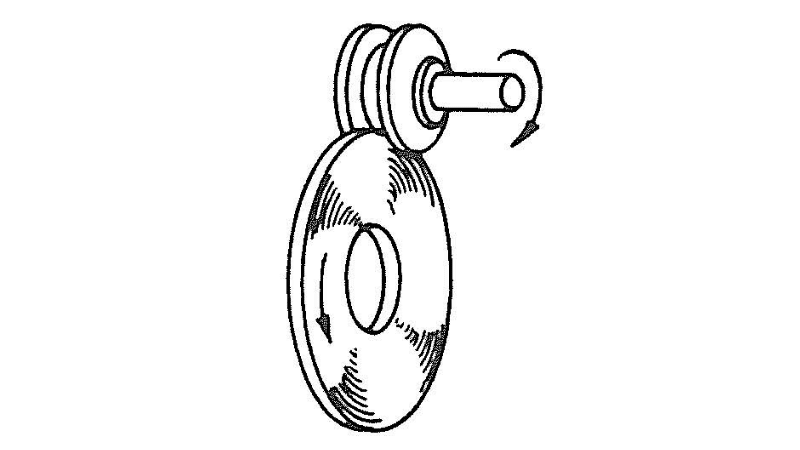

Seam welders are driven by a motor and a gear-reducing unit imparting rotary motion to the welding wheels in one of three forms: knurl drive, gear drive or friction drive.

The knurl drive is commonly used on coated metals because the knurling breaks up coatings on the metal surface and minimizes “pickup” on the welding wheel. The knurl drive has a great advantage over the gear drive if appearance of weld is not paramount. The knurl drive is the most positive of the three in avoiding “slippage” between driving wheels and the parts being welded.

The gear-drive mechanism is important in many types of work. If the surface of the welding wheel must be flat and free from markings of any kind for such particular work as the seam welding of propeller blades, then there is no alternative but to use a gear-drive mechanism. This is for the reason that knurl- or friction-drive mechanism might cause slippage between the drive wheel and the welding wheel resulting in burned welds.

Advantages of the friction-type drive are that the peripheral speed of the seam-welding wheels – or the surface speed of the work passing through the wheels – is constant at all times regardless of the wear on the wheel.

Applications for Seam Welders

Resistance seam welding machines are used to make welds that are gas or liquid tight. Seam welding is used for making lap joints. Good examples include seam welding the out-turned flange of an automotive gas tank, catalytic converter shells and aircraft tanks.