Resistance Welder Evaluation & Certification

Preventative maintenance of welding machinery is vital to the success of your resistance welding operation. That’s why T. J. Snow has developed an annual Welder Certification, Calibration and Inspection Program. This comprehensive preventative maintenance program for your welding equipment will ensure that your resistance welders are operating at optimal performance.

Inspection and Evaluation of Your Resistance Welding Machines

The functions and systems of the resistance welding system will be examined, inspected and tested using calibrated equipment. Minor fixes can be addressed during the inspection. Any major issues will be brought to management's attention.

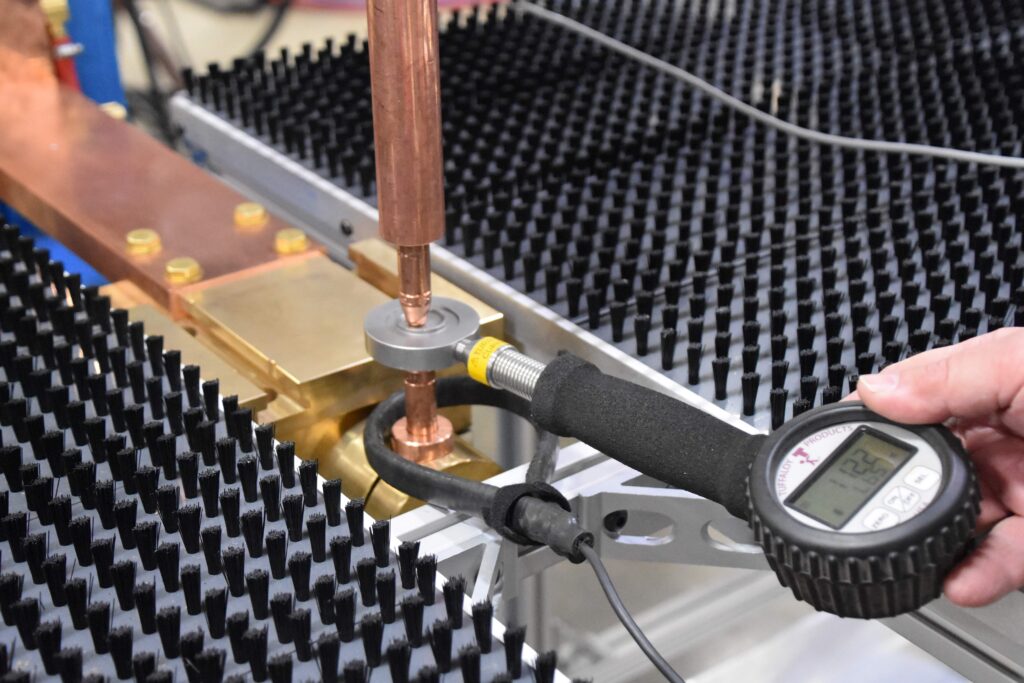

Secondary Resistance Check

The resistance at each secondary joint connection will be tested using a calibrated micro-ohm meter.

Force Consistency Check

Force consistency will be tested using a calibrated force gauge.

Current Consistency Check

Current consistency will be tested using a calibrated current monitor.

System & Component Evaluation

We will evaluate secondary bolts, water cooling system, electrodes and tooling, air system, air filter, air lubricator and weld control.

Welding Calibration Performed by the Experts

All preventative maintenance tests will be performed by one of our AWS (American Welding Society) Certified Resistance Welding Technicians.

Tools Used for Spot Welder Calibration

Most routinely used resistance weld checkers and force gauges need to be calibrated annually to make sure they are reading properly. T. J. Snow offers scheduled and as-needed calibration for the following resistance welding current monitors and force gauges:

| Manufacturer | Description | Part Number |

|---|---|---|

| Tuffaloy | Force gauge, weld force probe | 601-3000DLC |

| Tuffaloy | Weld checker, calibration, repair | 601-5000DLC |

| Amada / Miyachi | Weld checker, calibration, repair | MM-315A |

| Amada / Miyachi | Weld checker, calibration, repair | MM-315B |

| Dengensha | Weld scope | WS-100 |

| Dengensha | Weld scope | WS-80 |

Routine Inspection is Key!

Remember, if your weld analyzing tool isn’t calibrated and reading properly you could be damaging your machine or producing bad welds unknowingly.

Routine evaluation is the most effective way to be sure your resistance weld checker is reading properly, and that you’re seeing appropriate results in production.