Dressing electrodes refers to the re-cutting of the face of the electrode back to its original profile. The dressing of the electrode face is very important because it’s the diameter of that face that gives us the current density in our weld. The larger the face, the larger the area that the current has to go through. The bigger the area the current has, the more energy spreads out resulting in a cold weld.

There are several methods that we can use to dress electrodes.

1.File

We do not recommend using a file because we are unable to cut the face to a flat configuration leaving grooves in the face.

2. Sandpaper

We also do not recommend using sandpaper because the sandpaper grit can become embedded into the soft copper tips.

You should use hand-dressing tools with caution and should be properly trained on how to use these tools so that we get the proper face cut we desire. We recommend Electrode Dresser’s YNR-8F Tip Dresser.

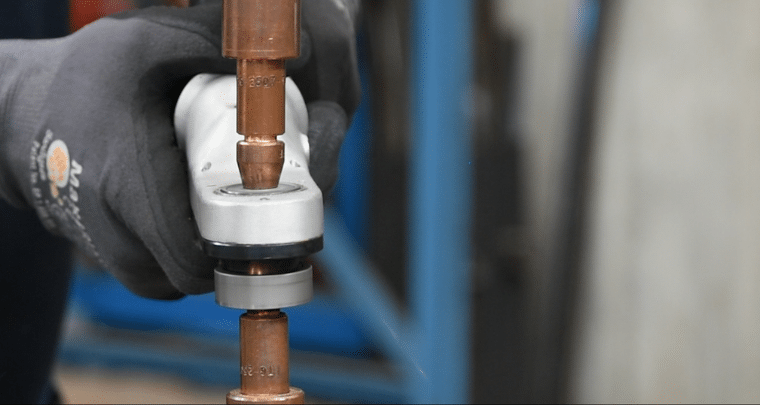

4. Cutter or a Mill

The best way to get the electrode back to its true face is to use a cutter or a mill. The number one cause of bad welds is found in the face of our electrodes. When we have customers call in because of issues with their welds, we first tell them to replace with brand new electrodes and then to test their welds again without changing any other parameters. Typically, you can get 2-3 dressings of that electrode before you actually can’t use it anymore. Every time you dress your electrodes, you are going to use up some of that material on the copper electrode which will inevitably result in a little bit lower life of that electrode.

If you have any issues or questions about dressing your electrodes or would like to purchase proper dressing tools, call T. J. Snow at (423) 894-6234.