What is Expulsion in Resistance Spot Welding?

In a resistance weld, expulsion is the forceful ejection of molten metal from the weld. Expulsion can occur at the tip to workpiece interface or at any faying surface. Expulsion is caused by the lack of containment of the expanding molten material between the electrode tip faces.

Is Weld Expulsion a Good Thing?

While it may look cool in car commercials, expulsion is not the sign of a quality resistance weld. In fact, it should be our goal to minimize expulsion as best as we can. It’s fallacious to think that increasing current (ensuring expulsion) to get the weld hot enough will somehow result in a quality weld. As we mentioned above, expulsion is the molten steel not being contained underneath the electrodes. This is material being ejected from the weld nugget. From a quality perspective, we want to make our weld nugget as strong as possible. Expulsion could potentially compromise the structural integrity of the part being welded.

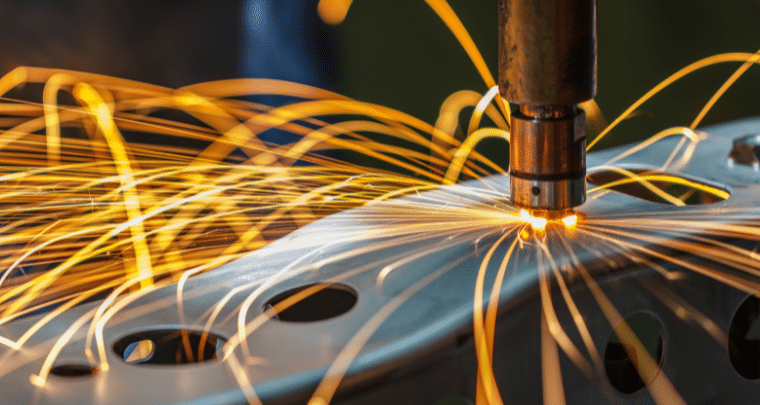

Expulsion is the forceful ejection of molten material from the part being welded.

What Causes Expulsion?

There are many factors that can cause expulsion. One reason could be that there is contamination underneath the surface of the electrode to the material (interfacial resistance). Since the electrodes and the part create an electrical circuit, you must have a good conductivity for the current to flow through the electrode into the material you are welding. Another issue that may cause expulsion is low weld force, increasing resistance and heat generated in the faying surface of the weld to uncontrollable limits. Poor part fit up can also be a major contributing factor to material expulsion.

Safety Hazards

Due to the nature of expulsion, there are obviously some safety hazards to be aware of. Not only could the hot metal expelling out from the part burn the operator, but there is also a fire hazard if the sparks ignite a flammable substance.

What About Expulsion in Projection Welding & Cross Wire Welding?

It is an entirely different story when we talk about projection welding and cross wire welding. We will almost always see some expulsion in these types of

Expulsion is not uncommon in cross wire welding.

welds. This expulsion is normally contained with the nest area of the part being welded. Therefore, it does not have the same effect as in spot welding relative to material expulsion as a safety hazard.