Unitrol Accustart

Proper tip force is very important in the formation of a resistance weld.

Accustart easily connects to the pressure switch input terminals on any brand resistance weld control.

Ensuring Proper Tip Force for Resistance Welding

Tip Force should be reached before the 1st half cycle of weld current flows… and this Tip Force should not rise above the necessary force during the weld. See the Unitrol Technical paper on Tip Force for a through discussion.

The UNITROL ACCUSTART using the latest microcomputer technology contains a differential pressure transducer. As it subtracts back pressure from working pressure from the welder’s air cylinder, the effects of flow control or internal air cylinder leakage will be detected and prevent welding until proper TIP FORCE has been reached.

* Tip Force Too Low

- Excessive Heat

- High Expulsion (sparks)

- Large Poor Looking Welds

- Drastic Reduction in Electrode Life

* Tip Force Too High

- Inadequate Heat

- Brittle Welds

- Limited Nugget Penetration

| MODEL | DESCRIPTION | DIMENSIONS W X H X D |

|---|---|---|

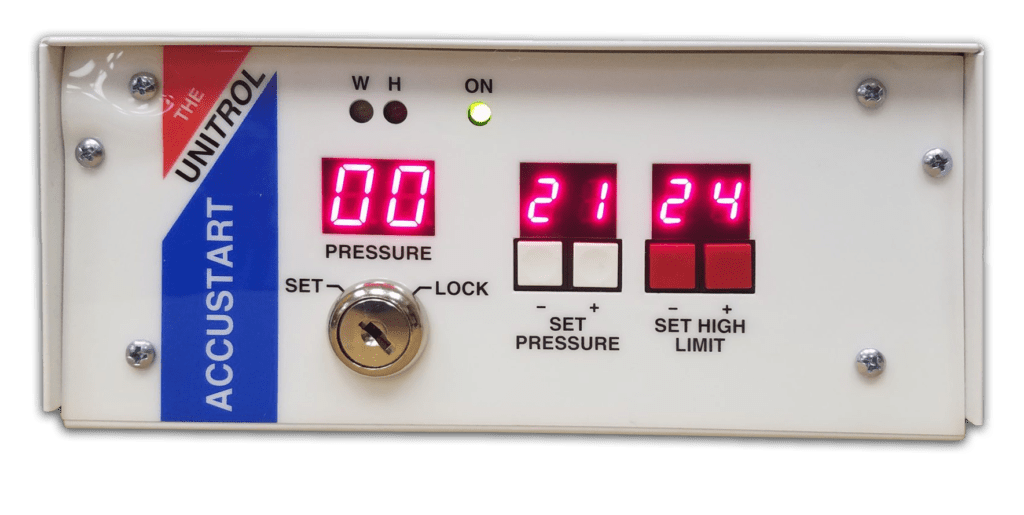

| 9580 | Waits until differential air pressure equals value shown in the SET PRESSURE window of the system. At that time, a relay contact is closed to satisfy the PRESSURE SWITCH circuit in the existing welding control. | 8″ x 3½” x 5″ |

| 9581 | Waits until differential air pressure equals value shown in the SET PRESSURE window of the system. At that time, a relay contact is closed to satisfy the PRESSURE SWITCH circuit in the existing welding control. The unit also compares differential air pressure to the value shown in the HIGH LIMIT window of the system. If the pressure exceeds this value, a second relay contact closes for 1 second while an alarm sounds. Simultaneously, an indicator light glows and remains on until the next weld starts. | 8″ x 3½” x 5″ |

| 9582 | All the functions of the 9581 ACCUSTART plus a built in electronic AIR PRESSURE SETTING SYSTEM that automatically sets the pressure to match the value shown in the SET PRESSURE window. Unit comes complete with a remote 1/2″ air regulator and air pressure gauge. | 11½” x 3½” x 5″ |

Technical Specifications:

- Voltage 115 VAC, 50/60 Hz (230 volts available at no additional charge)

- Relay contact rating 120 VAC @ .3 amperes, 30 VDC @ 1 ampere

- Warranty – 1 year

ACCUSTART comes complete with:

- 36 ” cable for connection to welding control

- keylock switch to prevent setting changes

- (2) 1/4″ poly tubing x 1/4″ NPT male fittings

- (1) 36″ long 1/4″ green poly tubing

- (1) 36″ long 1/4″ red poly tubing

- instruction/installation booklet