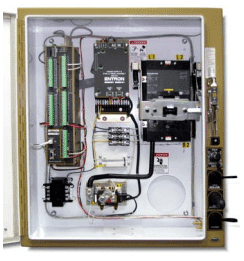

Entron EN6021 Single Phase AC Constant Current Controls

Standard with every control !

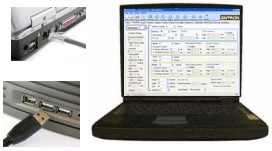

Communication software provides PC interface for USB or Ethernet interfaces.

Constant Current

Current Sensors:

- Control adjusts current output every cycle.

- No setup necessary for constant current operation.

- When optional secondary or primary coil is used, secondary amps are directly displayed.

- Current High, Low and Pre limits.

- Results of last weld available immediately.

- Pulse Width Monitor.

PLC Compatible

- PLC compatible via MODBUS Function Code 04, 16 and 43 via low cost serial or ethernet interfaces.

- Design your own operator interface.

- Actuate Weld Control Inputs from PLC, minimal interconnecting wires required.

Features

- USB B interface for ENLINK programming

- USB A Memory Stick Jack for Schedule backup

- USB A Memory Stick Jack for Weld Log storage

- Spot, Pulsation or Seam Sequence

- Programmable options: Slope, Preheat, Quench, Temper, Postheat

- Linked Programs

- External Schedule Select

- Event Outputs

- Advanced Error Outputs

- 100 Programs

- Repeat / Non-Repeat

- Water Saver Timer

- Programming in phase shift or kA

- 24 VDC flexible I/O (16 in/16 out); some mapable between weld functions, events and simple I/O sequences (16 in/16 out available for sequencer)

- I/O Sequencer/Programmer

- Stepper with Force and Current Presets

- Diverse schedule capabilities provide maximum application versatility

- 2) 4-20 mA / 0-10V analog input & output provided for pressure sensing & control

- Program Select

- Retraction

- Weld Log (28,800 entries) and Error Log (1,000 entries) with real time clock

- PLC compatible via MODBUS

- Shorted contactor detection

Options

- Detachable 128 x 64 dots graphic (8 lines) LCD Program Pendant (RPP2) with data backup and 10N cable

- Primary or Secondary coils

- Program Lockout

- Operation Mode Switch (OMS) – Program Lockout & Weld/No Weld

- Pressure Sense & Proportional Valve

- Isolation Contactor

- GFI for portable guns

- Water Flow Switch

- RS232/485/Ethernet communication card

- 16 DC in, 16 DC out and 4 AC out I/O expansion card

- USB Memory stick for backup

Expanded Capabilities (Requires additional software and/or hardware)

OPTIONS:

-

- TO PROGRAM, YOU WILL NEED:

Program Pendant (RPP2) (P/N 730014-001): Detachable, hand-held pendant accesses all programmable variables and displays current and status.

– OR –

ENLINK 6000 (P/N 730014-010): Communication software provides PC interface for remote programming and monitoring of control.

-

- TO MEASURE CURRENT IN AMPS, YOU WILL NEED:

Secondary Rogowski Coils: (S5 – P/N 730014-005; S8 – P/N 730014-006) Available in 5″ or 8″ diameters. Provides actual secondary amperage measurements.

– OR –

Coil as part of Weld Transformer.

– OR –

Primary Coil (P/N 313022)

-

- I/O Expansion Card (P/N 730014-008): Provides additional 16 DC inputs, 16 DC outputs and 4 AC outputs.

- Communication Card (P/N 730014-007): Provides ability to network multiple controls using ENLINK 6000.

- Pressure Sense and Control Hardware

Using provided analog I/O or additional hardware:

-

- Differential sensors (P/N 730005-008)

- Single-ended sensors (P/N 730005-005)

- Proportional valves:

- 1/2″ port (P/N 730005-007)

- 1 1/4″ port (P/N 730005-006)

- GFI for portable guns

- RS232 Printer (P/N 730014-011)

- Data storage on USB memory stick (P/N 730014-003)

- Operation Mode Switch (OMS) (P/N 730014-004)

- Program Lockout PLS) (P/N 730014-009)

- Water Flow Switch (P/N 730005-009)

You might also be interested in:

Single Phase AC Controls

Inverter (MFDC) Controls

Three Phase DC Controls

Specialty Controls

Weld Checker