Controls for Resistance Welding iPAK MFDC Inverter Controls

Latest Generation of Advanced MFDC Inverters

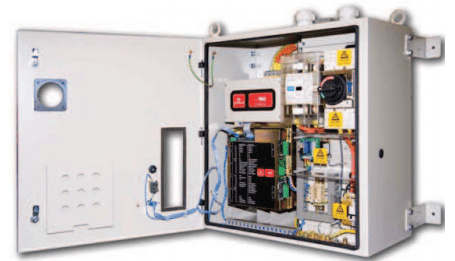

Control cabinet with door-mounted timer, up to 64 programs, constant current control and monitoring. Fitted into a sheet steel enclosure with circuit breaker, 24 VDC air valve power supply, appropriate line fusing, safety covers, and water-cooled MFDC Inverter Module. Optional hand-held pendant.

Control cabinet with door-mounted timer, up to 64 programs, constant current control and monitoring. Fitted into a sheet steel enclosure with circuit breaker, 24 VDC air valve power supply, appropriate line fusing, safety covers, and water-cooled MFDC Inverter Module. Optional hand-held pendant.

Features

- Spot / Repeat / Roll-spot / Seam (dual heat) / Seam (preheat)

- Pulsation, Upslope and Downslope

- Dual weld intervals per program (Preheat and Weld)

- 64 programs (internal or external selection)

- Constant Current regulation

- Current/Power Monitoring: High/Low limits and Pre-limit

- Proportional valve controller (0–10 V or 4–20 mA)

- Pressure Monitoring: High/Low limits

- Programmable blocking on fault

- Weld Log keeps history of recent welds

- Programmable outputs (events)

- Retract/High-lift control

- Single or dual gun operation

- Optional Constant Voltage regulation / Constant Power

- OHMA (Air over Oil) gun operation

- Up to 3 analog inputs (2 x 0–10 V, plus 1 x 0–10 V or 4–20 mA)

- Machine Sequencer Logic

- Chain – Weld programs may be linked together for multiple spot sequences

- Cascade configuration available – Up to 4 MFDC transformers

- High Current Output configurations available – up to 300 kA weld current capability, higher on special applications

You might also be interested in:

Single Phase AC Controls

Inverter (MFDC) Controls

Three Phase DC Controls

Specialty Controls

Weld Checker