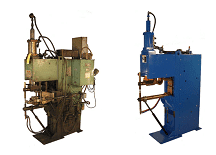

Example Applications of Microwelding and Microjoining in Industry

Examples courtesy of Unitek Miyachi Corporation. T. J. Snow carries the full line of Miyachi Fine Spot Welding Equipment.

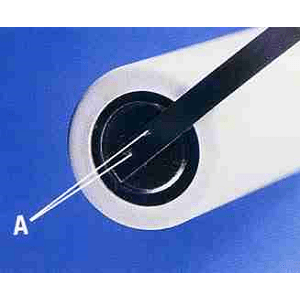

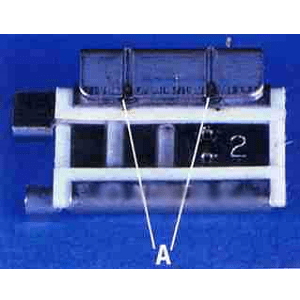

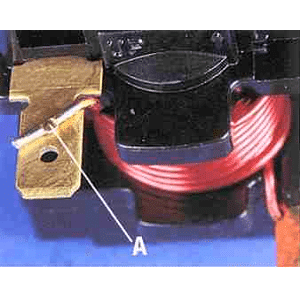

Automotive Ignition Module

Objectives: Strong weld joint, high production speed, low equipment cost.

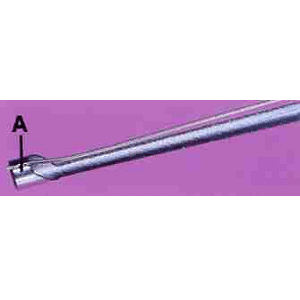

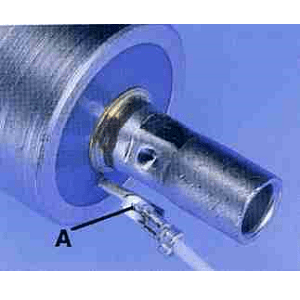

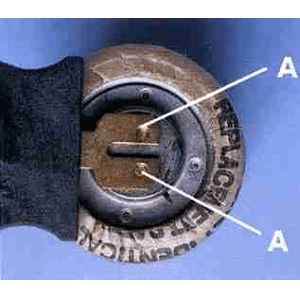

Cauterizing Tool

Objectives: Strong Weld Joint, minimum splash, precise energy control.

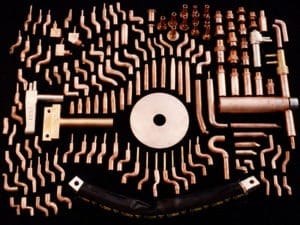

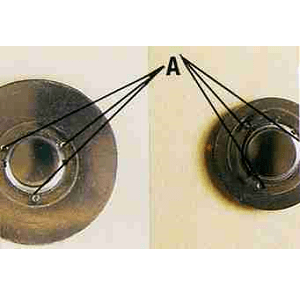

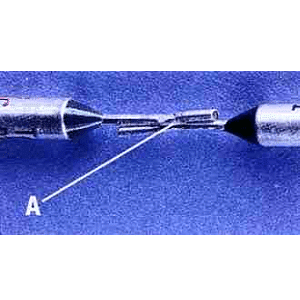

Air Bag Diffuser

Objectives: Strong weld joint, high production speed, low equipment cost.

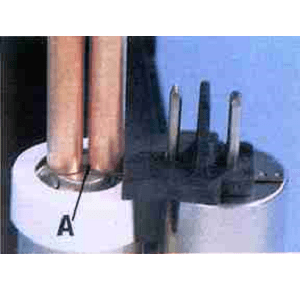

Detonator Module

Objectives: Strong Weld Joint, minimum wire deformation, low equipment cost.

Hair Dryer Heater Assembly

Objectives: Good electrical connection, maximum weld joint strength, and low equipment cost.

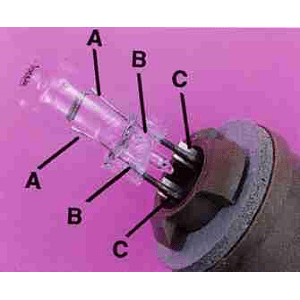

Halogen Filled Automotive Headlamp

Objectives: strong weld joint, minimum splash at high production speed, and long electrode life.

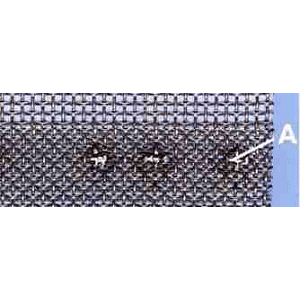

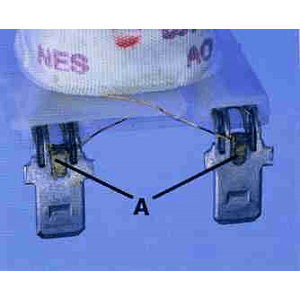

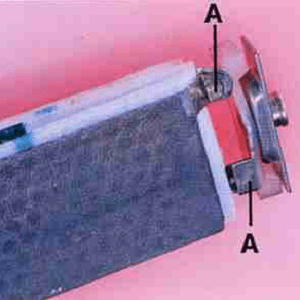

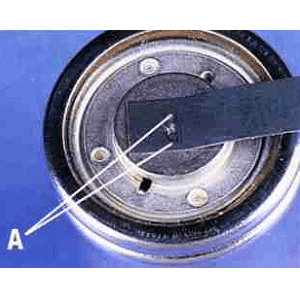

NiMH Battery Caps

Objectives: A strong weld joint with complete projection set-down and low equipment costs.

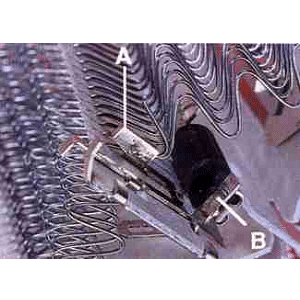

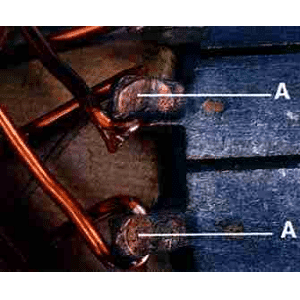

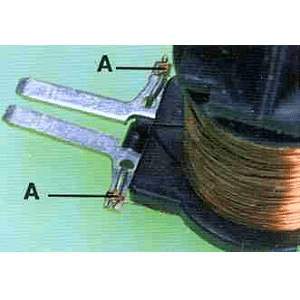

Electric Motor Wire Fusing

Objectives: Good electro-mechanical crimp connection, high speed production, low equipment costs. The Insulation on the copper magnet wire is vaporized from heat generated by the weld current flowing through the motor tang and around the copper magnet wire.

Appliance Solenoid

Objective: A good electrical connection, good weld joint strength, high speed production, and low equipment cost. The Insulation on the copper magnet wire is vaporized from heat generated by the weld current flowing through the terminal and around the copper magnet wire.

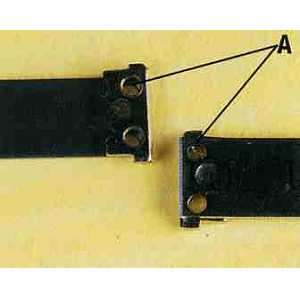

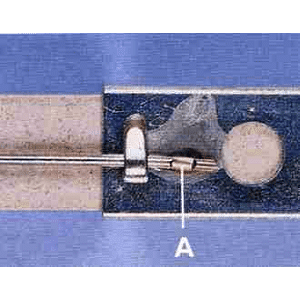

Relay Latch Plate Assembly

Objective: Strong weld joint, high production speed, and minimal weld splash.

NiMH Battery Tab

Objective: Good electrical connection, strong weld joint, and low equipment costs.

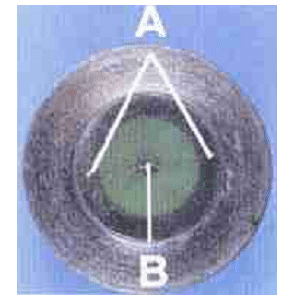

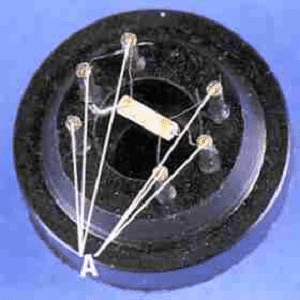

Power SCR (Solid State Relay)

Objective: Good electrical connection, maximum weld joint strength, and low equipment cost.

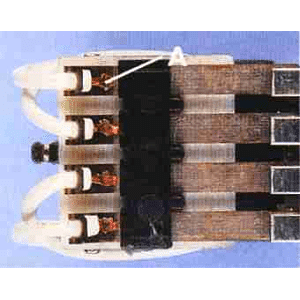

Prismatic Nickel/Cadmium Battery Assembly

Objective: Good electrical connection, good weld joint strength, high speed production, monitoring of welding current and voltage and low equipment cost. The welding of multiple battery plates required an Up Slope weld function to minimize material splitting.

Resistor Support Bracket

Objective: Strong weld joint, high speed production, and low equipment costs.

Control Module Assembly

Objective: Strong weld joint, high production speed, and low equipment costs.

Battery Pack Connector

Objectives: Strong Weld, consistent pull strength, and a minimum of battery cell marking.

Thermal Cut-off Assembly

Objectives: Good electrical connection, good weld joint strength, and high production rates.

Battery Pack

Objective: Good electrical connection and good weld joint strength.

Relay

Objectives: Good electrical connection, strong weld joint, and a high production rate.

Anti-Lock Brake System Solenoid

Objectives: Good electrical connections, good weld joint strength, high speed production, and low equipment cost. Insulating on the copper magnet wire is vaporized from heat generated by the weld current flowing through the terminal and diode lead and around the copper wire.

Element Assembly

Objectives: Good electrical connections and low equipment costs.

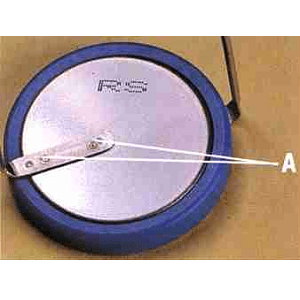

Lithium Ion Battery Tabs

Objectives: Strong, consistent weld, high production rates, SPC feedback.

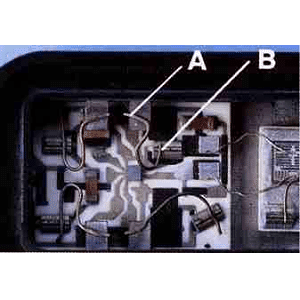

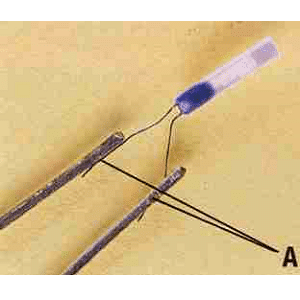

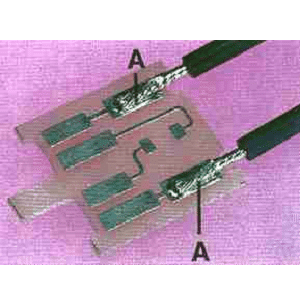

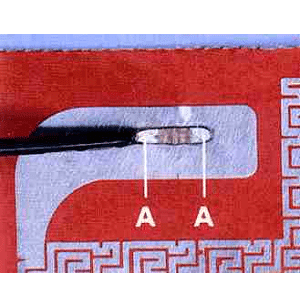

Automotive Sensor Printed Circuit Board

Objectives: Good electrical connection, low equipment costs. Reflow brazing was utilized by placing a pair of molybdenum tipped parallel gap electrodes on top of a single wire. A low weld current was then placed through the wire, generating sufficient heat to reflow the solder paste coated copper wire.

Flat Heating Element

Objectives: A good electrical connection, minimum joint strength, and minimum damage to the very thin heating element mounted on a rubber backing.

Microphone Plug

Objectives: Good electrical connection, good weld joint strength , and low equipment costs.

Sensing Device

Objectives: A good electrical connection and low equipment costs.

Battery Tab

Objectives: A strong weld, good electrical connection, and high production speed.

Prismatic Battery Tab

Objectives: A good electrical connection, high production speed and minimum marking.

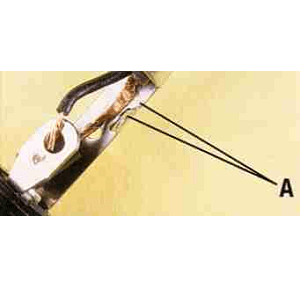

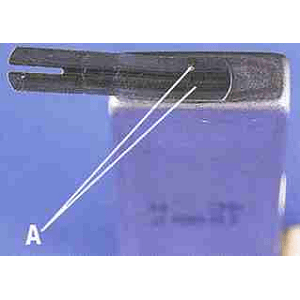

Relay Terminal Connection

Objectives: A strong weld joint, complete capture of all wire strands, and long electrode life.

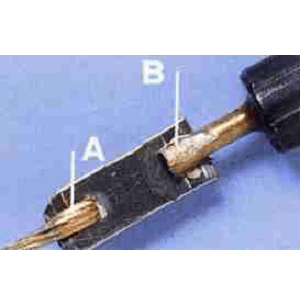

Cal Rod Heating Element

Objectives: A strong weld joint, complete capture of all wire strands, high production speed, and long electrode life.

T. J. Snow carries a full line of Microwelding and microjoining equipment, and would be happy to help you decided what is right for your job. We have both new and used equipment for you to choose from.